What Are the Safety Protection Devices for Conveyor Belts?

Conveyor Belts (commonly used in mining, ports, power plants, chemical industry, and other fields) are core equipment for material conveying.

However, during operation, they are prone to equipment damage or safety accidents due to faults such as deviation, slipping, overload, and tearing.

Therefore, targeted safety protection devices must be equipped, which can be divided into 10 categories by function.

Note: A summary table is provided at the end of the article for quick overview.

I. Belt Deviation Protection Devices

When a belt deviates from the center line, it may cause minor issu

es such as edge wear and material spillage,

or more serious problems like jamming and shutdown. Belt deviation protection devices are divided into two categories: "

monitoring and alarm" and "automatic correction".

Functions and Characteristics

Deviation Switch (Monitoring Type)

Equipped with two-stage triggering: When the belt deviates 10-30cm from the center line (first stage), an audible and

visual alarm is activated to prompt intervention; when the deviation exceeds the safety threshold (second stage), emergency shutdown

is enforced to prevent fault escalation.

Structure: Mechanical contacts or photoelectric sensing, installed on both sides of the belt, with a response time ≤ 0.5 seconds and

resistance to dust interference, acting like an "electronic guardrail" for the belt.

Automatic Deviation Correction Device (Correction Type)

It can actively "pull back" the deviated belt through mechanical/hydraulic structures without shutdown:

Self-aligning idler: Pure mechanical design, which uses the friction of the belt to drive the idler rotation for passive deviation correction

(low cost and maintenance-free);

Hydraulic deviation corrector: Active drive with stronger correction force, suitable for wide belts (e.g., 1.8m-wide coal conveying belts in ports).

Application Scenarios

All conveyor belts, especially long-distance (>100m) and wide-width (>1.2m) belts (e.g., main transportation belts in mines, coal conveying belts in power plants).

II. Belt Slipping Protection Devices

When the friction between the belt and the driving drum is insufficient, the phenomenon of "slow belt and fast drum" (slipping) will occur,

which may cause minor material accumulation or more serious problems like overheating and fire due to friction. This device monitors the

speed in real time to intercept risks in advance.

Functions and Characteristics

When the belt speed drops to 70%-80% of the rated speed (customizable), it first gives an alarm for early warning; if slipping persists,

it enforces shutdown to prevent the risk of fire caused by friction between the belt and the drum.

Structure Types

Speed sensor: Magnetoelectric type (contact-type synchronous speed measurement with the belt) or photoelectric type (non-contact,

identifying marks on the belt surface), with a speed measurement accuracy of ±0.5%, acting like a "speedometer" for the belt;

Drum-linked detector: Directly connected to the driven drum, with mechanical triggering, strong resistance to dust and humidity (suitable for

humid underground environments in mines), and no need for complex calibration.

Application Scenarios

High-load and high-speed belts (e.g., underground coal conveying belts in mines, ore conveying belts in ports), to prevent slipping caused by

material overload and drum material adhesion.

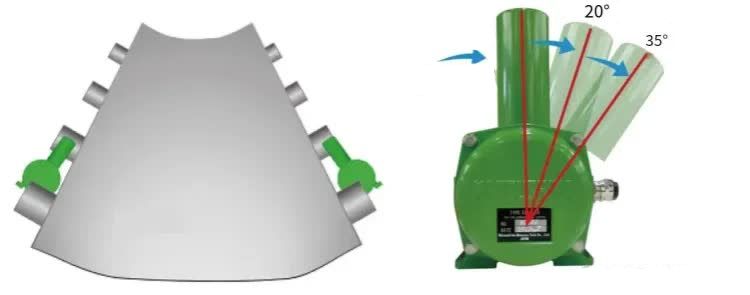

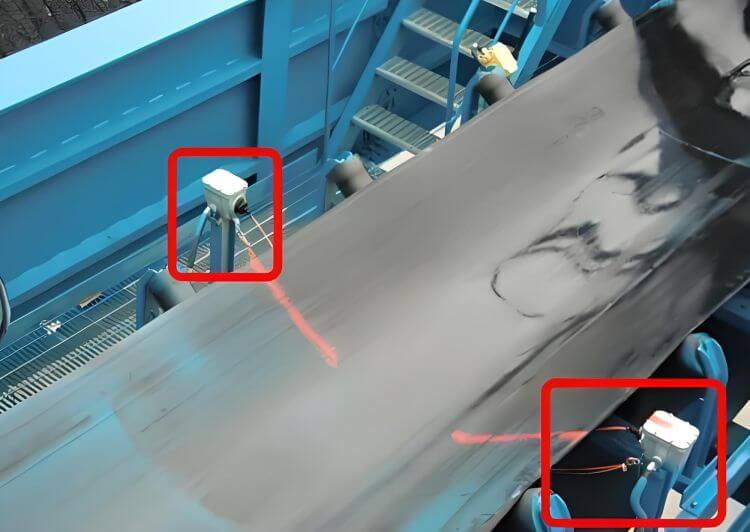

III. Belt Tearing Protection Devices

Sharp edges of ores, metal impurities, and other substances are likely to scratch the belt, causing longitudinal tearing.

If shutdown is not performed in time, the tear will spread rapidly, leading to the scrapping of the entire belt.

This device can quickly intercept tearing faults.

Functions and Characteristics

Once a belt tear (tear >50mm) is detected, it immediately triggers shutdown + alarm to prevent the tear from spreading.

Structure Types

Contact type (steel cable/plate type): Steel cables are embedded in the belt, and the switch is triggered when the cable breaks due

to tearing; the switch is triggered when the plate is squeezed by the torn belt, featuring high mechanical reliability but requiring direct contact with the belt;

Non-contact type (ultrasonic/infrared type): Ultrasonic waves scan the internal structure of the belt, and infrared rays identify changes in surface flatness,

with no wear and long service life, suitable for high-dust environments (e.g., raw material belts in cement plants), acting like performing a "CT scan" on the belt.

Application Scenarios

Belts conveying materials with sharp impurities (e.g., ore belts in mines, construction waste treatment belts), to accurately intercept "invisible hazards".

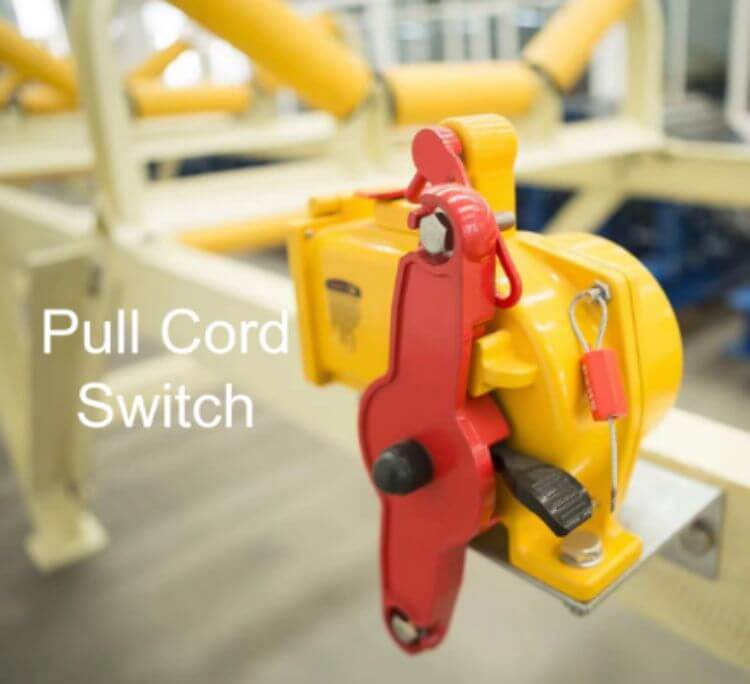

IV. Emergency Shutdown Protection Devices

In case of emergency situations such as personnel straying into the area, equipment jamming, or fire, the belt needs to be "shut down with one key".

This device is the final safety line and is divided into three types: along-the-line pull rope, emergency stop button, and emergency pull cable.

Functions and Characteristics

Pull rope switch: One switch is installed every 30-50m along the belt; pulling the pull rope at any position triggers instant shutdown,

covering the entire length, like wrapping a "safety rope" around the belt;

Emergency stop button: Red mushroom-head buttons are installed in the operation room and at the head/tail of the belt; pressing the button cuts off

the power immediately, with a response time <0.1 second, enabling more convenient "one-key shutdown";

Emergency pull cable: Made of steel cable (tensile strength ≥500N), suitable for complex paths such as curves and slopes; pulling the steel cable triggers shutdown,

filling the protection blind spots in special terrains (e.g., mountain belts in mines).

Application Scenarios

Pull rope/button: All belts (mandatory standard configuration by the state);

Emergency pull cable: Belts in the wild and complex terrains (e.g., mountain belts in mines), solving the problem of "unreachable and unpressable".

V. Overload Protection Devices

Belt overload will cause motor overload and belt stretching deformation. This device equips the belt with overload protection devices

from three dimensions: flow, tension, and current, which can detect problems in time and reduce potential safety hazards.

Functions and Characteristics

Belt scale (flow monitoring): Dynamically weighs the material; when the weight exceeds the limit, it first gives an alarm and then links

with the feeder to reduce the feeding amount (closed-loop control), acting like an "electronic scale" for the belt;

Tension sensor (tension monitoring): Monitors the belt tension in real time; when the tension exceeds the threshold due to overload,

it directly shuts down the belt to protect the "skeleton" of the belt;

Motor overload protector (current monitoring): Monitors the working current of the motor; when the current exceeds 1.2 times the rated current,

it automatically cuts off the power supply, featuring low cost and easy maintenance, acting as a "current bodyguard" for the motor.

Application Scenarios

High-flow belts (bulk cargo in ports, grain reserves, raw material belts in cement plants), to prevent chain faults caused by material accumulation.

VI. Anti-Reversal Protection Devices

Core Logic

After the shutdown of an inclined belt (inclination angle >15°), the gravity of materials is likely to cause the belt to reverse,

which may lead to minor material backflow or more serious belt stacking and tearing. The anti-reversal protection device can firmly lock the running direction.

Functions and Characteristics

Ratchet backstop: Pure mechanical structure (ratchet + pawl), no power dependency, with a reliability >99%, suitable for medium and low-speed belts

(e.g., underground hoisting belts in mines), acting like a "mechanical lock" for the belt;

Belt-type backstop: Realizes braking through the friction between the brake belt and the drum, featuring simple structure and low cost,

but with slight wear during braking, suitable for light-load belts;

Hydraulic backstop: Hydraulic drive, with stable braking and small impact force, suitable for high-speed (>2m/s) and heavy-load inclined belts

(e.g., ore hoisting belts in ports), acting like a "hydraulic brake" for the belt.

Application Scenarios

Inclined belts (underground hoisting in mines, inclined raw material conveying in cement plants, sand and gravel conveying belts in hydropower stations),

solving the problem of "material backflow".

Appendix: Summary Table of Conveyor Belt Safety Protection Devices (Quick Reference Version)

| Type of Protection Device | Common Specific Types | Core Function | Structure / Operating Characteristics | Typical Application Scenarios |

| 1. Belt Deviation Protection Device | ① Two-Stage Deviation Switch ② Automatic Deviation Correction Device (Self-Aligning Idler, Hydraulic Deviation Corrector) | ① Monitor the deviation amplitude of the belt from the center line; issue first-level deviation alarm and second-level deviation shutdown (to avoid belt wear / material spillage); ② Automatically correct belt deviation without shutdown. | ① Mechanical contact type / photoelectric type, installed on both sides of the belt (10-30cm from the center line), response time ≤ 0.5s; ② Mechanical structure (self-aligning idler) or hydraulic drive, passive / active correction, no electrical failure risk. | All conveyor belts (especially long-distance and wide belts) |

| 2. Belt Slipping Protection Device | ① Speed Sensor (Magnetoelectric / Photoelectric Type) ② Slipping Detector (Linked with Drum) | Monitor the actual running speed of the belt; when the speed is lower than the set value (e.g., 70%-80% of the rated speed), issue an alarm and shut down (to prevent overheating, fire, and material accumulation caused by friction between the belt and the drum). | ① Non-contact (photoelectric) or contact (magnetoelectric) type, synchronous speed measurement with the belt / drum, accuracy ±0.5%; ② Directly installed on the driven drum, mechanical triggering, strong resistance to dust interference. | High-load belts (e.g., coal conveying belts in mines and power plants) |

| 3. Belt Tearing Protection Device | ① Contact Type (Steel Cable Type, Plate Type) ② Non-Contact Type (Ultrasonic / Infrared Type) | Detect whether the belt has longitudinal tearing (e.g., belt scratched by sharp impurities in materials); shut down immediately (to prevent tear expansion and belt scrapping). | ① Contact type: Triggered by the steel cable / plate when the belt is torn, high mechanical reliability but requiring contact with the belt; ② Non-contact type: Scan the belt integrity through ultrasonic waves, no wear, suitable for high-dust / humid environments. | Belts conveying ores, construction waste, and other materials with sharp impurities |

| 4. Emergency Shutdown Protection Device | ① Pull Rope Switch (Along-the-Line Arrangement) ② Emergency Stop Button (Key Positions) ③ Emergency Pull Cable | In emergency situations (e.g., personnel straying into the area, equipment jamming), manually cut off the power to shut down the belt (serving as the final safety line); ③ Trigger shutdown by pulling the steel cable, covering belts in complex terrains. | ① Pull rope switch: One switch installed every 30-50m along the entire length of the belt, triggered by pulling the rope, covering the entire stroke; ② Emergency stop button: Installed in the operation room and at the head / tail of the belt, push-type, instant response; ③ Steel cable material (tensile strength ≥500N), with anti-corrosion shell, suitable for belts in complex paths such as curves and slopes. | ①② All conveyor belts (mandatory standard configuration); ③ Field and complex terrain belts (e.g., mountain belts in mines) |

| 5. Overload Protection Device | ① Belt Scale (Flow Monitoring) ② Tension Sensor ③ Motor Overload Protector | Prevent the belt from bearing more than the design load: ① Monitor material flow and alarm when exceeding the limit; ② Monitor belt tension and shut down when overloaded; ③ Monitor motor current and cut off power when overloaded. | ① Belt scale: Installed under the belt, dynamic weighing, can link with the feeder to adjust the flow; ② Tension sensor: Installed on the tensioning device, real-time tension feedback; ③ Electrical protection, low cost and easy maintenance. | Bulk cargo (coal, ore) conveying belts in ports |

| 6. Anti-Reversal Protection Device | ① Ratchet Backstop ② Belt-Type Backstop ③ Hydraulic Backstop | Prevent reversed rotation of inclined belts (inclination angle >15°) after shutdown (to avoid material backflow and belt stacking damage to equipment). | ① Mechanical structure (ratchet + pawl), no power dependency, reliability >99%; ② Belt-type: Braking through friction between the brake belt and the drum, suitable for medium and low-speed belts; ③ Hydraulic drive, stable braking, suitable for high-speed / heavy-load belts. | Inclined belts (e.g., underground and hoisting belts in mines) |

| 7. Temperature and Smoke Protection Device | ① Temperature Sensor (Drum / Bearing) ② Smoke Sensor | Prevent fire caused by friction: ① Monitor the temperature of the drum / bearing, alarm and shut down when overheated (e.g., >80℃); ② Detect smoke generated by friction and provide early fire warning. | ① Contact-type temperature probe (high-temperature-resistant material), installed on the drum end cover; ② Photoelectric smoke sensor, high sensitivity, can link with fire extinguishing devices. | High-speed and long-distance belts (e.g., coal conveying belts in power plants, chemical belts) |

| 8. Material Blockage Protection Device | ① Blockage Switch (Rotary / Capacitive Type) ② Level Sensor | Detect material blockage at hoppers and chutes (to avoid belt overload / deviation caused by accumulated materials); alarm and shut down when blocked. | ① Rotary type: The blade stops rotating when blocked by materials, triggering the switch; ② Capacitive type: Detect through the change of material dielectric constant, non-contact, suitable for viscous materials. | Belts with hoppers / chutes (e.g., cement and grain conveying belts) |

English

English Español

Español Русский

Русский